|

What is a Technics SL-23?

This belt drive, DC Servo turntable was the affordable model in the 1976

line up. I always thought it looked great. It has a massive S shaped tone

arm and a rather nice cueing lever. The unit wasn't popular

on eBay, so the price remained very reasonable with only one other bidding

on it. The unit was described as working order, but

that wasn't quite true.

On arrival it was found the belt was missing. A search on the web indicated

it needed a 0.6mm thick, 5.16mm wide 56.9cm inside circumference

belt. Dick Smith Electronics sells a pack of 11 turntable belts,

and one was found to be suitable.

Belt size. Measured as 24.3" The drum on the turntable is 7.8", giving a

circumference of 24.5". The belt must be tight enough to not fall off the inner turntable rim, and not too tight to stretch to the drive spindle.

The platter now rotated.

Connecting it to an amplifier and trying a test record, after checking

stylus weight to be 1.75gms, found that one channel wasn't working.

Opening up the unit and tracing the wiring through, found that the audio

cable as it passed through the grommet in the metal back panel was intermittent.

The grommet makes the cable pass through a U that had caused the

cable to fail over the years. Shortening the cable by 10cm and resoldering

the connections inside, on the PCB the very fine wires from the tone arm

connect to, fixed the problem. This PCB is under a metal shield plate held

by two screws. The audio cable used is very low capacitance, from the units

CD-4 compatible heritage. The whole cable could be replaced with newer

higher capacitance cable and it would not cause any problems. CD-4 is long

dead.

We now had two working channels.

The turntable has a built in strobe so that the speed accuracy can be seen,

even though the mains isn't a good short term reference. The speed stability

of 33.33rpm was suspect, and 45rpm was just terrible. Touching the fine

speed adjustment pots would stop the platter completely. Another

search on the net indicated the pots, electrolytics on the servo board

and the speed select switch have caused problems for others.

The 16mm 5k Linear pots, with fluted shafts where replaced from suitable

units from Dick Smith Electronics (R 7553). Note that the shafts

need trimming so the knobs do not stick up too high.

The speed select, ON/OFF switch was dismantled and cleaned with electrical

CO Contact Cleaner. This switch has two bolts that hold it together,

making the dismantling easy. It has many small parts! Be carefull not to loose any.

The speed was now not adversely effected by touching the switch or speed

trimmers. They did what they were supposed to do.

We were making progress, but speed stability was still a problem.

The speed was still randomly wrong. Enough to make using the unit annoying,

so the electrolytics on the DC Servo board were replaced. Electrolytics

can dry out, or leak over time, so just replacing them all is cheap and easy. It

cost all of $1.50 to buy new caps. I used a

Soldapullt and solder wick to get to the capacitor leads. Note that

the leads of the caps bend flat to the

PCB, so care is needed in removing them. If you apply too much heat to the PCB, you will lift tracks and need to replace the connections with wire. Modern caps are also smaller.

The little PCB is mounted near the center of the turntable via two screws.

There are 10 flying leads attached, but it is easy to work on the board

without removing them.

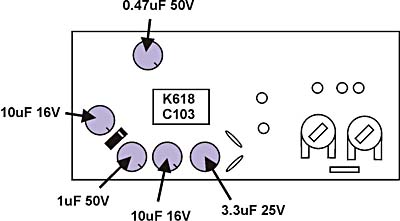

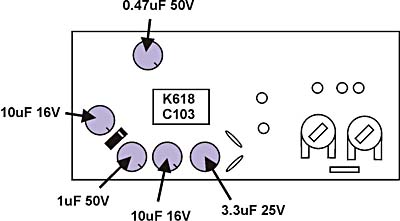

The Servo PCB top side of my unit is like:-

Capacitors from Jaycar Electronics used were:-

1 x RL-6410

2 x RE-6066

1 x RL-6414

1 x RL-6422

This fixed the speed problem. Just like new.

I have been informed some units have 6 electrolytics that need replacing. There may be a second 3.3uf/25V just to the right of the one in the above diagram.

The unit didn't have the original headshell, but a workable, possibly

better substitute. The headshell was fitted with a SANYO MG-28 cartridge

and matching ST-28 stylus. The replacement for the stylus is a Goldring

D.565 SR, and this was obtained at a local Hi-Fi store before playing any

irreplaceable vinyl. This stylus has a conical tip. An elliptical stylus

is more Hi-Fi, but we should probably change the cartridge before worrying

about that, and at our age, we couldn't here the difference anyway.

The cartridge alignment protractor from www.EnjoyTheMusic.com

was used to mount the cartridge in the best location in the headshell.

We also had to put one of the nylon washers between the cartridge and headshell

to get the head on view of the stylus cantilever to be perpendicular

to the record.

The unit now works as intended.

I've spent more time listening to the music, looking at the beautiful album

artwork, and recalling the memories of what we were doing at the

time the music was new, than I have worrying about the turntable set up.

I have an old CBS Stereo Test Record and this unit passes all the tracking

tests on it. So it seem to be set up OK. It even plays most of the records

that I know skip on lesser turntables.

However there is one thing to be improved, the stylus. An elliptical

stylus, instead of the conical, would result in less record wear. Sanyo

has never been a famous cartridge maker, and most people that did make

them have gone out of business. The mass of the tone arm makes this unit

unsuitable for many modern cartridges, such as the available Ortofon

units. There are suitable Shure , Audio Technica and

Goldring available that do have elliptical stylus, and we may look

into that in the future. The Audio Technica AT95E may be the best

bet.

RIAA Preamplifier

To use the turntable with a computer Soundcard, a RIAA preamp based

around a single LM833 opamp is used.

This is because a Soundcard has an AUX or LINE IN level input that does not match the output of a Magnetic Cartridge, or the way records were encoded. Modern vinyl records were not recorded with a flat frequency respone, but with an RIAA response. To get a flat response back, you use a RIAA preamplifier to reverse the effect and boost the signal to AUX levels. The PCB kit KC5159- Universal Stereo Preamplifier, from Jaycar Electronics, based on the Silicon Chip Magazine April 1994 article was the starting point.

This was built into a small anodized aluminum case. We added a 7812 regulator, bypass caps, a largish electrolytic, a standard plug pack

socket, 470R and small red LED power indicator, 4 RCA connector strip and a large earth binding post to make a very low noise RIAA to Line Level Preamp box. This is powered by a floating universal plug pack.

To make the dual supply PCB run from a single supply, add 47K resistors from +/-15 V to ground at the PCB supply tracks so that our turntable signal earth and box use is connected to the PCB 0V,

which will actually be 6V as far as the internal regulator is concerned. The regulator is bolted to the case, but insulated from it. The binding post and RCA earth conectors are also connected to PCB 0V.

For recording and editing we use Cool Edit 96 and for processing and MP3 generation, Audiograbber.

Recording and ReMastering with Reaper

We have recently used Reaper, our Digital Audio Workstation for recording. It allows us to render out tracks as 16 or 24bit files and do loudness processing (in effect remastering) with Izotope Ozone if required. We have these tools for our own recording and mastering anyway.

Some items that may be useful

Home

Copyright © 1995-2023 Art & Technology. All rights reserved.

No reproduction is permitted without explicit written permission.

|

|